OPTIMIZING THE STORAGE POTENTIAL OF RACKS

Assessing the Durability and Makeup of the Concrete

Warehouse efficiency relies heavily on the stability and strength of its infrastructure. Among the critical elements, the concrete slabs forming the foundation play a pivotal role in determining the storage capacity and safety of rack systems. Maximizing rack capacities while ensuring safety demands meticulous attention to the concrete slabs on which they stand. Core tests, a method of evaluating the concrete’s strength and composition, emerge as a vital tool in achieving this balance.

UNDERSTANDING CORE TESTS

Guaranteeing Strength and Dependability

Core testing is a fundamental process that entails the extraction of cylindrical samples, commonly referred to as cores, from concrete slabs. These samples are carefully drilled from the slabs and subsequently subjected to a battery of tests within laboratory settings. These assessments are crucial as they provide engineers with invaluable insights into multiple facets of the concrete’s composition and structural integrity. By conducting these tests, professionals can determine critical properties such as compressive strength, density, moisture content, and various other essential characteristics. This comprehensive evaluation aids in making informed decisions regarding the concrete’s quality and suitability for specific applications, ensuring robustness and reliability in construction endeavors.

IMPACT ON RACK CAPACITIES

Compressive Strength Validation

Core testing stands as a pivotal procedure, primarily geared towards validating the compressive strength of concrete slabs. This particular strength metric holds immense significance as it directly dictates the load-bearing capacity of these slabs, exerting a profound impact on the weight they can effectively support. In the realm of warehouses equipped with intricate rack systems, this capacity assumes critical importance, serving as the backbone for safely accommodating and storing substantial loads. Through the meticulous execution of core tests, engineers embark on a quest to confirm if the concrete meets the stringent strength standards mandated for such structures. This meticulous evaluation ensures that the racks within these warehouses can confidently shoulder their designated weight capacities without compromising the overall structural integrity of the edifice, thereby upholding safety standards and operational reliability within these spaces.

IDENTIFYING WEAKNESSES AND DEFICIENCIES

Long-Term Safety and Durability

The comprehensive nature of core testing transcends mere confirmation of concrete strength; it serves as a diagnostic tool, unearthing potential weaknesses or deficiencies residing within the slabs. These meticulous examinations often unveil a spectrum of issues, ranging from voids and cracks to irregular density or inadequate aggregate distribution. These imperfections, when left unnoticed, possess the potential to burgeon into significant challenges. Early identification of such concerns through core testing empowers engineers to initiate precise interventions, whether through targeted repairs or strategic reinforcements. This proactive approach not only averts imminent structural failures but also acts as a cornerstone for fortifying the long-term safety and durability of warehouse racks. By addressing these underlying vulnerabilities, core testing contributes significantly to enhancing the structural robustness and resilience of the warehouse, ensuring a secure environment for operations while mitigating the risk of potential hazards.

TAILORED RACK DESIGN AND PLACEMENT

High Standards in Warehouse Management

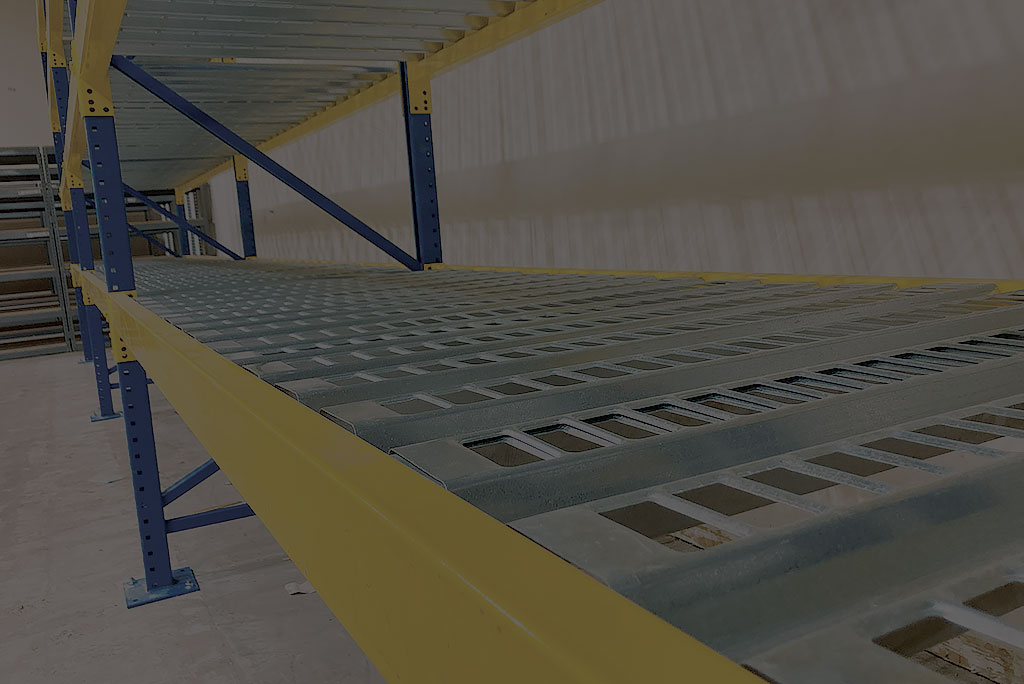

By using what they learn from core tests, engineers get the important information to design rack systems that match how strong the concrete floors are. They really understand how much weight each part of the warehouse floor can handle. Then, they carefully decide where to put the racks so that the weight is spread out well, especially in areas that aren’t as strong. This careful planning doesn’t just use the warehouse space in the best way, it also makes sure it’s super safe. It’s like creating a perfect balance between using the space well and keeping everything really secure. Doing this isn’t just about storing things better; it shows how well they understand the structure and how great they are at running the warehouse smoothly.

IMPLEMENTATION AND BENEFITS

Enhancing The Warehouse's Performance

Using core testing regularly in warehouse upkeep and building brings many benefits. It helps us check how strong the warehouse is and find any issues early on. Doing these tests often means we catch problems with the concrete early and fix them before they become big problems. This keeps the warehouse safe and helps us plan ahead to prevent issues. Also, doing these tests regularly helps us keep an eye on how strong the warehouse is. This makes sure our storage systems are reliable and the warehouse stays safe. Plus, it helps us spend money wisely by making smart choices about repairs or future work, saving us money in the long run and making the warehouse work better.

When it comes to running warehouses smoothly, understanding how strong the concrete floors are is super important for how much weight the racks can hold. Core testing is a crucial way to check if the floors are really strong, letting us put more weight on the racks while still staying safe. Spending on these tests doesn’t just make warehouses work better and faster, it also builds a stronger base that protects against risks, making sure the warehouses keep running smoothly for the long haul.